Current situation

- Several computer systems required for

- Laser control

- Control loop (e.g. Photon-camera)

- DDS, DAC‘s…

- External data exchange via GbE, PCIe;

- Implementation of own HW is complicated

- Proprietary systems (manufacture-specific)

- Not flexible, limited functions

This is our challenge:

powerBridge Computer is developing a benchmark-capable,

high-performance, series-capable, integrated system for industrial automation based on quantum computing.

Goal, Perspective and Potential

Task for the interdisciplinary team

Our task is to transfer MicroTCA.4 as a technical standard from research, science and industry to user-orientated quantum technology.

The well-engineered MicroTCA.4 standard – a development largely driven by Helmholtz/DESY (Deutsches Elektronen Synchrotron) in Germany – forms the technological basis of our developments.

Advantages of MicroTCA.4

- Established standard for >20 years

- Standard for research in the field of

- high-performance physics

- Developed in partnership with industry and science

- Open standard of the PICMG (cf. DIN)

- Developed in Europe – (used in the USA)

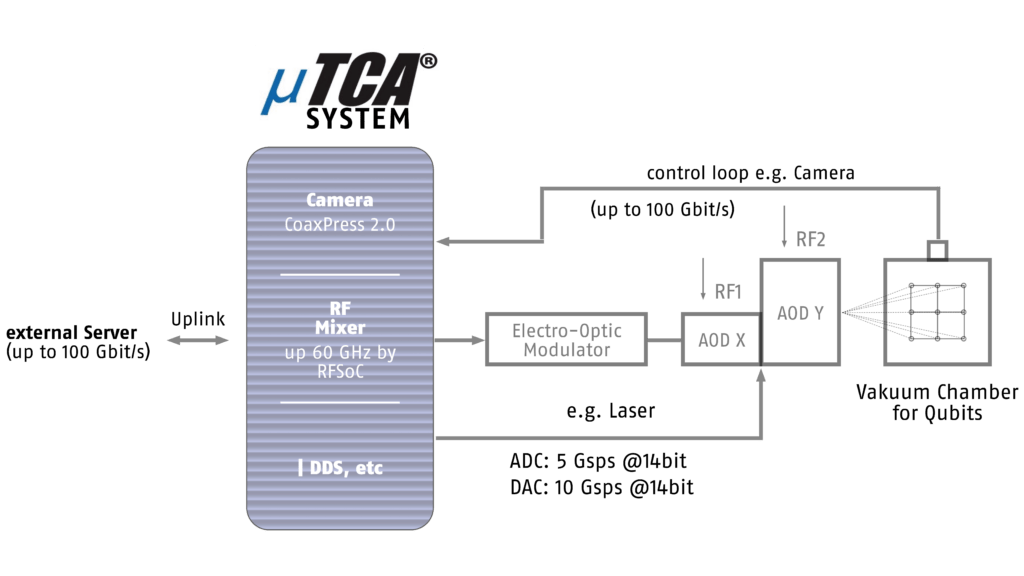

Solution: Integrated system

powerBridge Computer is transferring best-practice solutions from high energy physics applications to the industrial needs (and requirements) of quantum technology.

Prototypes are already in the test phase with potential users.

Integrated system based on MicroTCA.4

- Triggering and control loop in one system

- Fastest communication fabrics in the system

- (PCIe 4.0, 40GbE)

- Connection via 100GbE with external servers

MicroTCA-based, integrated pBC system solution

powerBridge computer solutions

- Large selection of I/Os, FPGA (RFSoc, MPSoC), CPU, DDS

- Easy to develop own boards on MTCA as an open standard

- FPGA RFSoC up to 6 GHz (60 GHz in testing) incl. front end for analogue signal pre-filtering and amplification

- CoaXPress 2.0 for cameras for speeds of up to 8x 12.5 Gbit/s (=100 Gbit/s)

- Everything integrated in one system

CONCLUSION

Fast – simple – scalable

- Fast board development (<1 year), as individualisation of COTS products

- Proven, global industry standard for physical engineers

- Everything in one system ->

- Fastest data feedback | control loops

- Innovative interdisciplinary team ->

- Manufacturer, PBC, customer

- Experience in the initiation, project planning and realisation of innovation processes

- Proven successful implementation in an industrial context